What is Factory Automation (FA)?

In modern manufacturing, greater efficiency and higher precision in production are required. To achieve this, the adoption of Factory Automation (FA) systems and industrial robots is rapidly increasing. FA systems are designed to automate production lines and manufacturing processes, creating an optimized production workflow.

Benefits of FA Systems

-

1.Increased Productivity

FA systems can operate 24/7, significantly enhancing productivity by eliminating downtime and optimizing workflows.

-

2.Workforce Reduction

In Japan, where an aging population and declining birthrate have led to labor shortages, automation allows companies to allocate human resources to tasks that require human judgment and creativity while automating repetitive processes.

-

3.Cost Reduction

While FA systems require an initial investment, maintenance costs are generally lower than labor expenses. Automation reduces the workload on employees and helps cut personnel costs.

-

4.Improved and Consistent Quality

Inspection is one of the key processes handled by FA systems. Automated inspection using cameras and sensors eliminates human inconsistencies, prevents oversight, and allows for record-keeping, ensuring uniform product quality.

-

5.Enhanced Workplace Safety

FA systems and robots can take over hazardous tasks, reducing risks for human workers. For example, robots can operate in high-temperature or high-pressure environments and handle hazardous chemicals, ensuring worker safety while maintaining efficient production.

Types and Roles of Robots

Robots play a crucial role in FA systems. The following types of robots are commonly used in production environments:

-

1.Industrial Robots

Most industrial robots are arm-type and operate within safety fences, allowing for high-speed movement. Other types include SCARA and parallel robots. These robots can perform various tasks depending on the end effector attached, such as gripping objects, tightening screws with drills, capturing images with cameras, or welding with welding machines.

-

2.Collaborative (Cooperative) Robots

Unlike traditional industrial robots that require safety fences, collaborative robots can safely operate in the same workspace as humans. This allows humans and robots to work together, enabling a more flexible production environment. However, they do not move as fast as industrial robots.

-

3.AGV (Automated Guided Vehicle) & AMR (Autonomous Mobile Robot)

These robots automate transportation tasks in factories and warehouses. AMRs can navigate optimally by detecting and avoiding obstacles in real time, improving efficiency in material handling.

FA Engineering Services Proposed by Kanetsu

At Kanetsu, we handle a wide range of products necessary for factory automation, from wires and connectors to control equipment, making our extensive product knowledge a key strength.

From harnesses and control panels to complete systems, we collaborate with trusted manufacturers with years of experience. We offer a one-stop service that covers specification meetings, design, material procurement, manufacturing, and delivery, providing high-quality engineering solutions from start to finish.

Process for FA System Implementation

-

- Consultation

- We listen to the customer’s needs and challenges, then determine the specifications and scope of implementation.

-

- Site Survey

- We check the layout and surrounding equipment to assess the feasibility of production and installation.

-

- Quotation

- Based on the specifications, we select equipment and systems, calculate the scale of the project, and estimate the time required for completion.

-

- Design and Manufacturing

- We carry out detailed design and manufacturing based on the specifications. The combination of robots and control equipment is optimized, followed by functional tests.

-

- On-Site Installation and Delivery

- We install and connect the equipment, conduct trial runs, and make necessary adjustments. We also provide teaching (operational training) before completing the handover of the system.

Features of Kanetsu’s FA Engineering Services

Robot System Implementation

For customers considering the introduction of robots in their operations, we propose the most suitable system design. We select the necessary components from a variety of machines, safety devices, and other equipment, providing comprehensive support from system proposal and design to assembly and startup.

Control Panel Manufacturing

We provide end-to-end support for control panel manufacturing, including design, component procurement, sheet metal processing, assembly wiring, and testing.

Whether it’s the production of new control panels and distribution boards or the updating of aging systems such as PLCs and servos, we offer consultation services for all your control panel needs.

Feel free to contact us for any inquiries related to control panels.

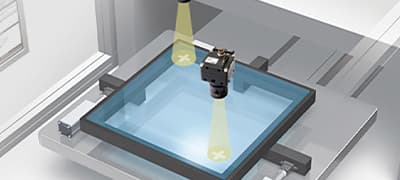

Introduction of Image Inspection Systems

We propose automated inspection systems that combine image devices and necessary equipment, replacing manual visual inspections that have traditionally relied on human eyes.This solution reduces and stabilizes inspection labor, helping improve product quality and prevent defective products from being shipped.

Equipment Assembly

We can manufacture equipment of all sizes, from small to large. We also accommodate requests for small lots and short delivery times.

From material procurement to PCB and harness manufacturing, assembly, and delivery, we offer a one-stop service with just one order form. You can rely on us for equipment assembly outsourcing services.

Delivery Record

| Delivery destination | System name | Main equipment used |

|---|---|---|

| pump manufacturers | Inserting and removing workpieces from hof machine (machine tending) | Collaborative robot (OMRON Corporation TM12) dedicated trolley (SUS Corporation ZFM-R602) |

| beverage manufacturer | Bottle crack and chip inspection | Image processing machine (OMRON F210) |

| packaging equipment manufacturers | Date printing inspection (expiration date) | Image processing machine (OMRON FH) |

| engine manufacturer | Engine block engraving inspection | Image processing machine (OMRON FH) |

| Fluid measuring equipment manufacturer | EtherCAT communication test equipment | PLC (OMRON NJ) |

| Fluid measuring equipment manufacturer | automatic screw tightening device | Screw tightening machine (Janome JR3000) |

| Waterworks Bureau | Drainage control panel replacement | PLC (OMRON C200H→CS1) |

| railway | PLC replacement for UPS control | PLC (OMRON C60P→CJ2) |

| university | PLC ladder learning kit | PLC (OMRON CPM2C) Touch panel (OMRON NS) |

| auto parts manufacturers | automatic lathe equipment | Articulated robot (Denso VS-087) PLC (OMRON CJ2) |

| housing material manufacturer | Board product wall thickness monitoring device | PLC (Mitsubishi iQ-R) Touch panel (Keyence VT) Measurement sensor (Keyence LK-G) |

| Petroleum product sales industry | Oil distribution center equipment replacement | PLC (OMRON C200HS→CS1) Touch panel (NT610C→NS10) |

| packaging equipment manufacturers | bottle alignment device | Parallel link robot (FANUC M-2iA/3S) |

| stage lighting manufacturers | Development support | Soft (DMX512) sheet metal painting assembly |

| resin molding manufacturer | Automatic transport between facilities | AMR (OMRON LD-250) |

| cable manufacturers | Winding wire automatic palletizing | Articulated robot (Fujikoshi SRA100-01) |

| auto parts manufacturers | AI inspection system for welding condition | Image processing machine (Cognex in-Sight D900) |

| glass manufacturer | Automatic transport between facilities | AMR (OMRON LD-90) |

| glass manufacturer | Automated flat glass deflection measurement | Measurement sensor (OMRON ZS) software design |

| Semiconductor manufacturing equipment manufacturer | gas cleaning unit | PLC, touch panel software design, unit production |

| Wind-power generation | Control box for wind power generation | Panel design, control box production |

| plant cultivation equipment | Control panel for plant cultivation equipment | control panel |